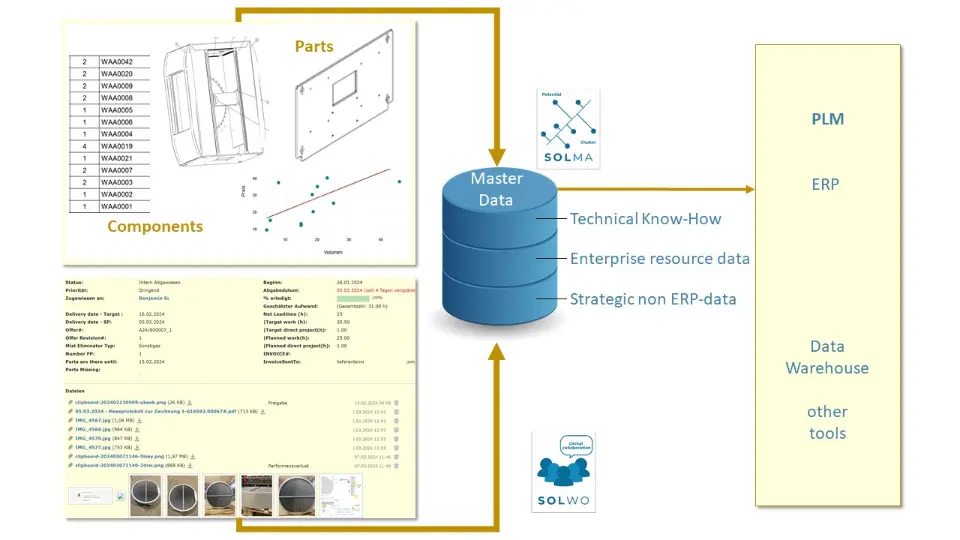

Rethinking master data – moving away from the pure ERP approach

For a long time, technical data was managed almost exclusively in the ERP system – focusing on material groups, costs, and work plans. But today, more is needed: True innovation power lies in engineering – and in the drawings. These contain the knowledge that will create value in the future.

Material costs often make up more than 40% of the order value – with project durations of up to two years.

Digitization as a turning point

The digitization of technical drawings changes the rules of the game. Instead of isolated departments, a shared data basis is created – AI-supported, networked, and ready for real value creation.

How AI is made ready for use

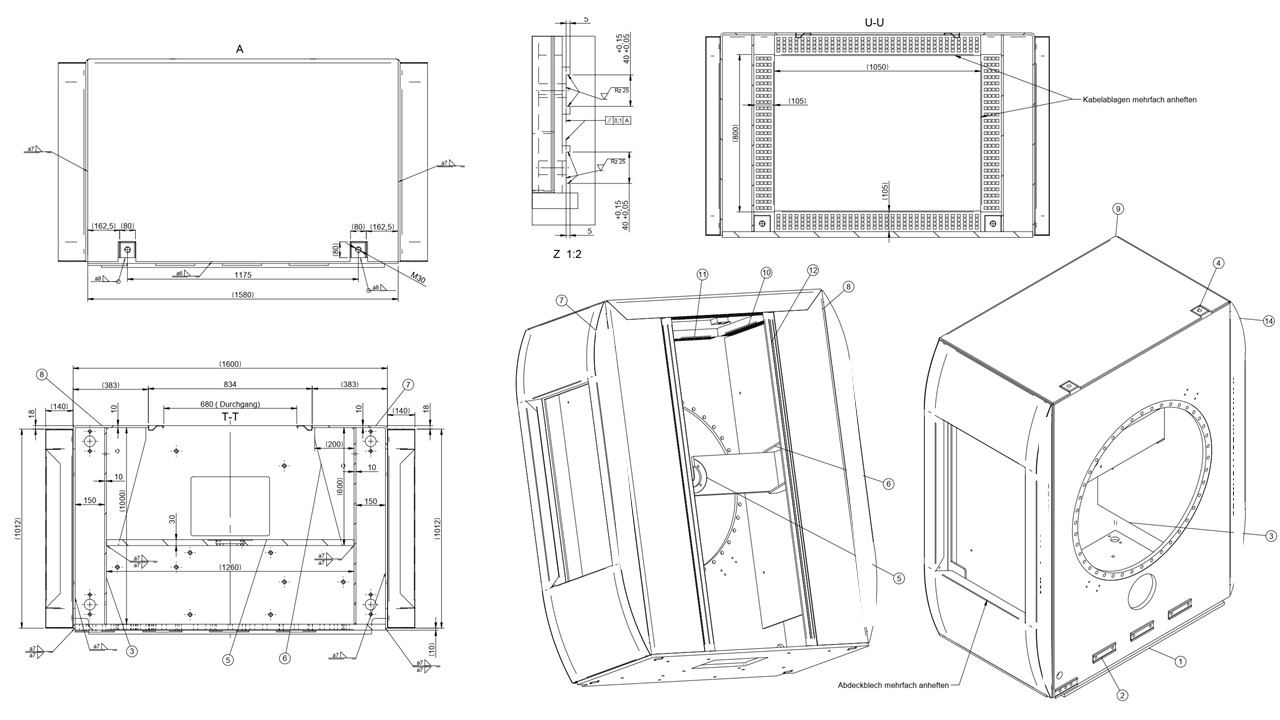

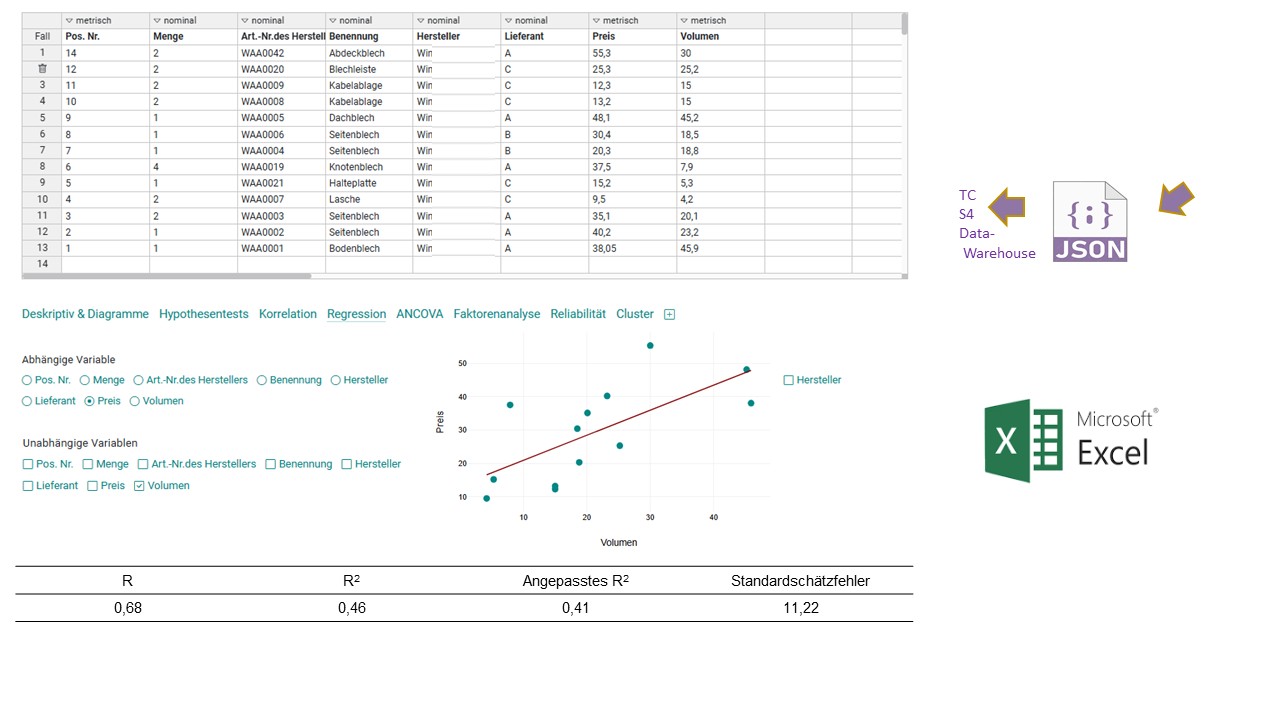

An example: A housing made of several sheet metal parts is fully digitized – including material, tolerances, and eBOM. This creates the foundation for precise analyses and valuable predictions.

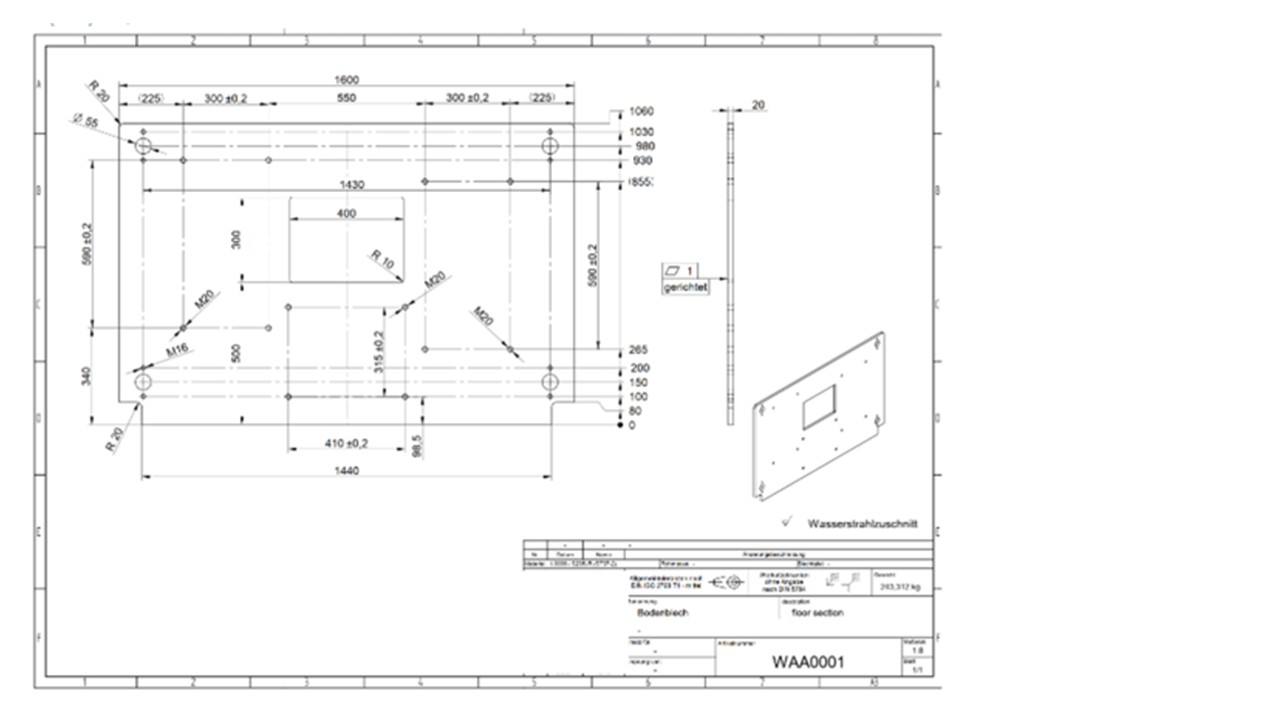

To subject the eBOM or mBOM of "WBA0005" to meaningful analysis, individual parts are of course needed, exemplified by "WAA0001".

Getting more out of drawings

Drawings often contain untapped value. AI-supported analysis uncovers this treasure – from seemingly similar parts, inconsistent prices, and hidden patterns arise well-founded decisions.

Practical example: Mechanical engineering successfully digitized

A mechanical engineer networks with system partners, exchanges technical data in real time, and uses regression models for offer analysis. Result: more trust, faster coordination, better negotiation basis.

What AI can read from drawings

Tolerances, geometries, interrelations

From this data, AI learns and complements classical materials management with real, substantively justified value creation.

SML & eCl@ss – Stronger together

SML describes technical features, eCl@ss classifies products. Together, they form the basis for data-driven decisions in purchasing, development, and engineering.

Goal: More reuse, lower costs, better planning reliability.

Integration into your existing IT landscape

Our "experts on demand" integrate seamlessly into your structures. They bring methods, tools, and solutions to close existing gaps – pragmatic, step-by-step, effective.